Chemistry of 3d printing

You do not need to know this to do 3d printing, but you might just be interested. Just as background on what I know, I have a Ph.D. in chemistry, and did a lot of work on free radical reactions for my thesis, though not polymerisation.

"Normal" Chemistry

Virtually all the organic chemistry taught in an undergraduate course is about positive and negative attracted to each other, and pairs of electrons moving around. Electrons really want to be in pairs. When you look at the structure of an organic compound, each bond is a pair of electrons.

Here is an example reaction. Each letter or pair of letters represents an atom, in this case hydrogen, carbon and bromine atoms. Straight lines between them indicate bonds - each line is a pair of electrons shared between the atoms at each end. Two straight lines together is a double bond, so four electrons.

Chemists use curly arrows to indicate the movement of electron pairs. The H of H-Br is somewhat positive, and the double bond of ethene is somewhat negative, so they are attracted. In the first step, one electron pair from the double bond moves towards the hydrogen. In the second step, this has given a new bond to the hydrogen, and now the electron pair between the H and the Br is going to move to the Br. In the third step, the electron pair on the Br is pulled to the C with a positive charge.

Free Radicals

Free radicals are not like that.

There is no charge (well, sometimes there is, but not relevant here), and more importantly, this is about a single electron. In fact, the driving force is the need for electrons to pair up.

In this example reaction we start with a chlorine radical - the big dot represents a free radical. The curly arrow has only half an arrow head - this is just one half of the pair moving. Note that the end of the process we end up with another chlorine radical, ready to react again.

Polymerisation

Polymerisation is a process whereby one molecule is linked to another, which is then linked to another and another to produce a long chain, potentially thousands of units long. The long chain is a polymer, the individual molecules you start with are monomers.

Sometimes the monomers are all the same compound, but not necessarily.

As an aside, plastics are made of polymers with some other substances added - usually a plasticiser for one.

Free Radical Polymerisation

This is a process of polymerisation involving free radicals; it is a common way to make polymers. Here is an example.

The R indicates a general organic group - it could be a benzene ring, which would give polystyrene, it could be -COOCH3, which would give polymethylmethacrylate (Perspex) and there are many other possibilities.

This is the basic reaction in your 3d printer.

Cross-linking

Polystyrene and polymethylmethacrylate are linear polymers - one long chain of monomers. What would happen if our monomer had two double bonds? Both double bonds could be part of a polymer chain - maybe the same chain, or maybe different chains. Now we have links between the different polymer molecules - cross-linking.

Monomers with multiple sites that can polymerise are often call cross-linkers (I have also seen them called oligomers, but that is not technically right - an oligomer is a short polymer, maybe up to a dozen monomer units).

Cross-linking makes the resultant material stronger.

Initiation

Something I have skipped over up to now is how we get a free radical in the first place. Once you have a free radical, the reaction will keep going because the sequence of steps starts with a free radical, and ends with a free radical. You have a chain reaction. This is called "propagation".

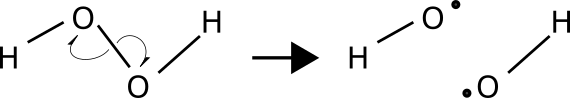

The first step is "initiation", and is where a free radical is produced. Or rather, where two are formed - we originally have a pair of electrons forming a bond between two atoms in a molecule, and break the bond, splitting the electrons one either side. This is called homolytic cleavage, in contrast to heterolytic cleavage, where the bond is broken, but the two electrons stick together, both going to the same atom.

Homolytic cleavage is rare because, as mentioned before, electrons like to be in pairs. You need a bond that is relatively weak, but also with similar atoms on either side. You also need the right conditions to trigger it - heat or electromagnetic radiation.

A simple example is hydroperoxide. The two atoms are very similar - both oxygen.

Peroxides will fall apart when heated - which can make them dangerous! Other initiators responds to light, including UV light; these are called a photoinitiators.

You can also use gamma-radiation to produce free radicals, if you happen to have a 60-cobalt source available; this is what I did for my Ph.D.

Termination

We also need to be aware of termination. This is when two radicals happened to bump together; they combine to form a bond - the reverse of the initiation step.

A free radical reaction involves one initiation step, numerous propagation steps and then one termination step.

3d Printing Resin

So at last we are ready to get to the resin used for 3d printing. There are three basic components. The photoinitiator to kick start the free radical reaction - but only when and where we want it, the monomer, often something like methylmethacrylate, and the cross-linker. There seems typically to be a few percent of the photoinitiator, though I have seen reports of higher amount, and about equal amounts of the monomer and cross-linker. There may be other components, such as dyes. A sensitiser may be used; I think this responds to UV light, and induces the initiator to fall apart to give the free radicals.

Companies tend to be a bit cagey because this sort of thing is commercially sensitive - though hard to imagine it is that difficult to determine with the right analytical equipment.

Comments

Post a Comment