Keeping Warm

I keep my 3d printer in the garage, which is not heated and is detached from the house. Today the BBC reports the external temperature is 3°C, and I guess the temperature inside the garage will be similar.

3d printing does not work well at low temperature. Chemical reacts are very temperature dependent, and I guess that will apply to the cross-linking process, even though it is "powered" by the UV light. Another factor is the viscosity of the resin, which is important because with each the plate rises up, and the resin has to flow into space, and then back out as the plate goes back down.

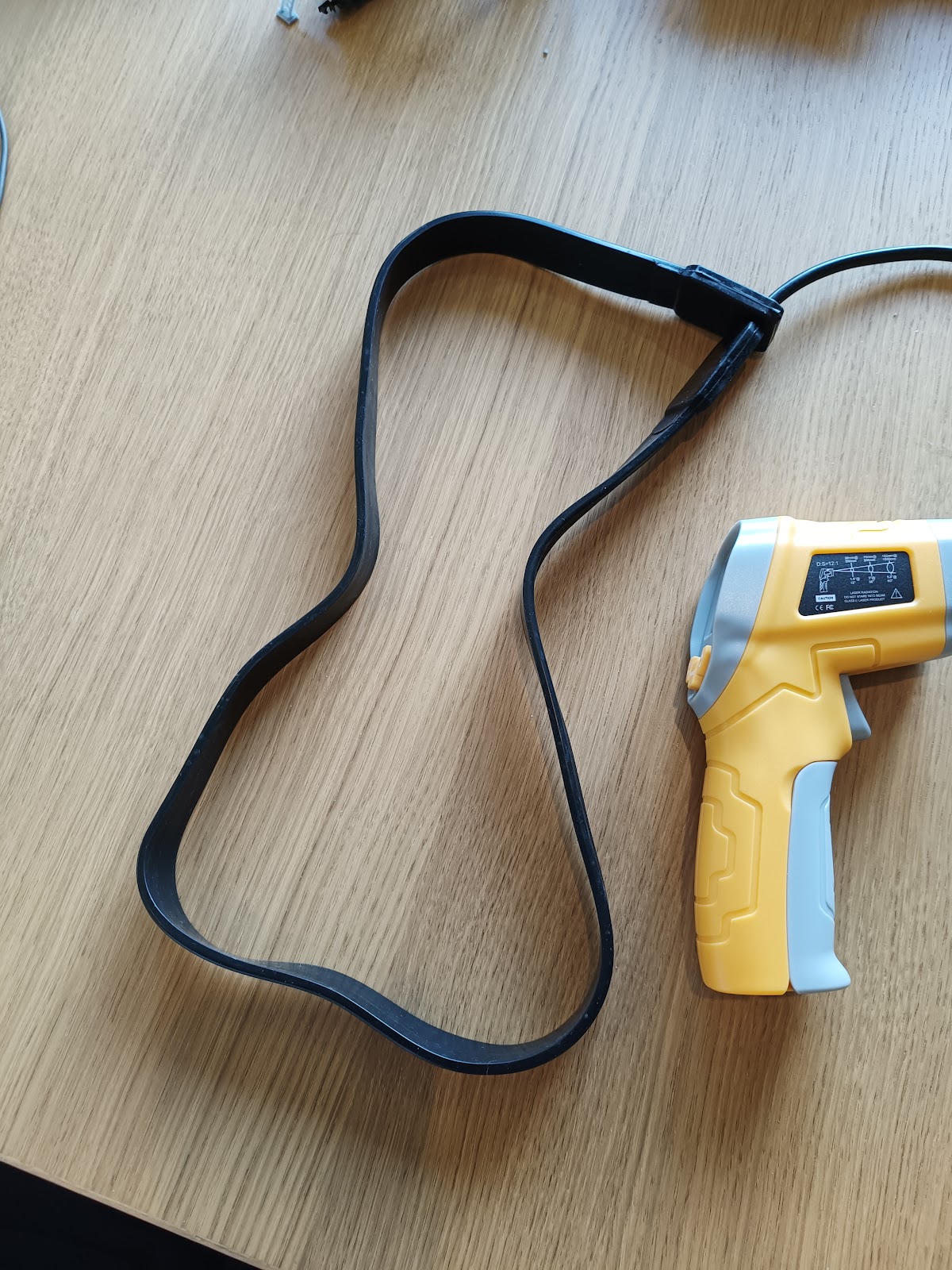

To circumvent that, I have purchased a heating strip designed for home brewers to keep their fermenting beer warm. It has a controller (not visible in the image).

The controller has a dot on the knob, and a series of dots on the housing, but the latter are not much help as the dot on the knob goes well beyond them. I will there estimate the angle in degrees clockwise from the mains-in lead. The off position is about -15; there is a click to the lowest setting at about 20. It goes up to about 275.

I also purchased an IR thermometer, which reports the temperature to 0.1, but the variation in results makes me think it is no better than accurate to 0.5. It seemed the beam was bouncing off the surface of the resin, and when at an angle I could see a spot on the wall behind it too; putting my hand in the reflected beam caused the reading to increase. My feeling is that it works better if the device is reading straight down.

The heater strip was just slightly to fat to allow the lid to go on the 3d printer, and I was also worried about the plastic melting, being in direct contact, though it turns out the strip did not get above about 25. I left the lid off, and covered it with a bag-for-life, which happens to be a suitable size.

I experimented with heating the tank before printing, and found that a setting of 90 gives a temperature of 25 around he edges, though the centre was only around 12. I turned it down to the minimum to start printing, and checked again after 30 minutes. It had cooled at about 20, but the movement of the plate was mixing t up so it was that temperature across the tank.

When it had finished, however, virtually nothing had stuck to the plate...

In hindsight, I think this was because the plate was cold at the start, so (after filtering the resin) I made a second attempt but now with the "bottom exposure time" increased from 35 to 60 seconds. This seemed to sort it, and most items printed okay (and where there were issues I think it was the model).

ETA: While I have mostly been successful if I do not try to print if the outside temperature is below 8°C, I have had one issue. The corners seem to be cooler, and consequently do not print properly.

If you look at the image, the model nearest the camera has split at the bottom, while the other models are fine. The solution, I think, is to keep stuff out of the corners while printing at low temperature.

ETA2 (25/Aug/24): Elegoo now do a heater, and I am using that instead. Not experience especially low temperatures, but I think is a better solution. For one thing the cover can be used.

Comments

Post a Comment