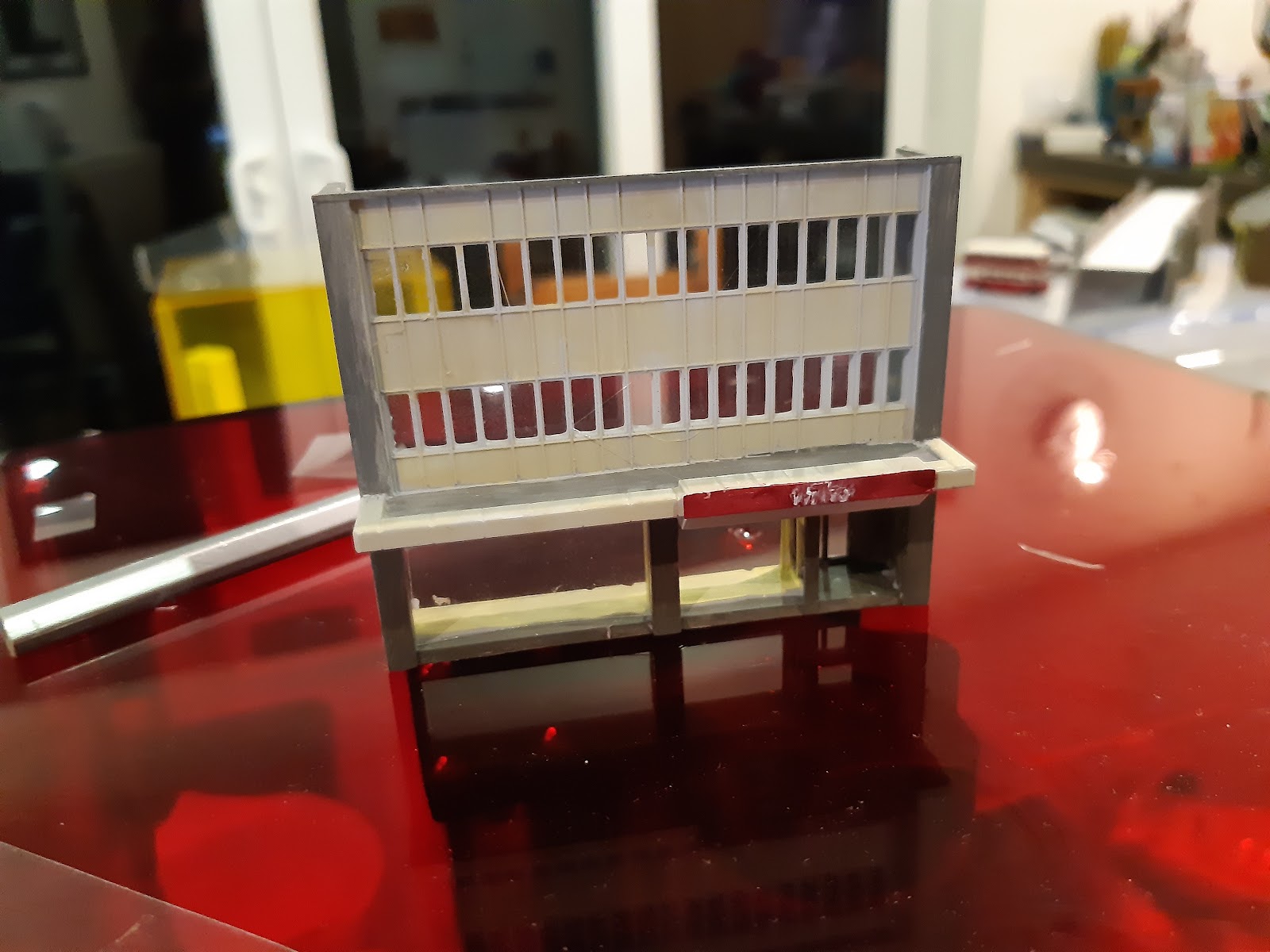

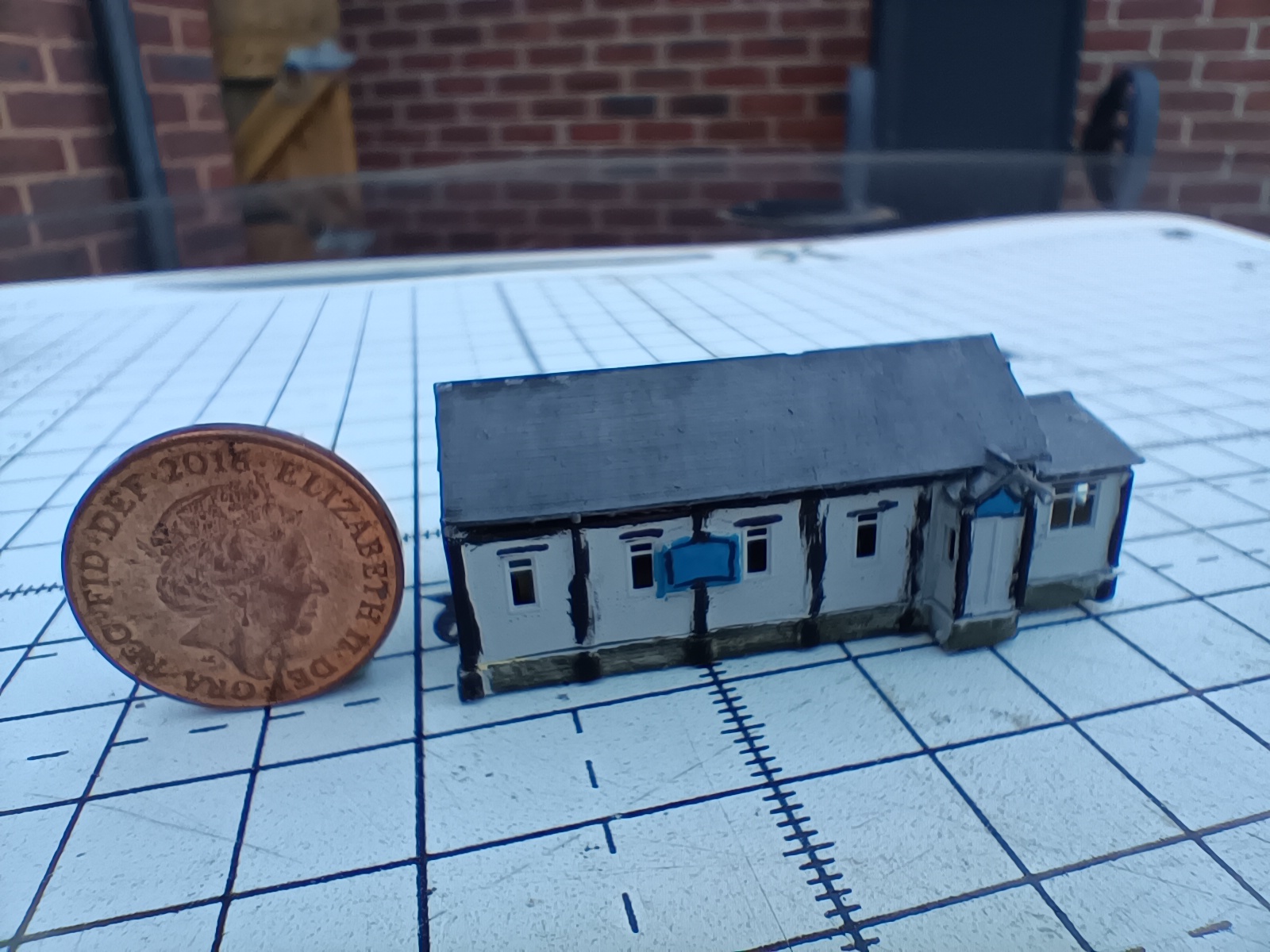

Preston City Mission

This is a delightful building on Corporation Street, as it meets the Ring Road, and I guess is the only wooden building left in Preston. I miscalculated the scale, and this is it at 1/420 scale (approximately T gauge), and just 5 cm long. The prototype was built in 1900 as the Railway Mission. Previously services had been held on the station platform allowing railway workers who were obliged to work on Sunday to worship. Some time around 1980 British Rail decided to sell the land, and it looked like it would go to a property developer, but the church raised funds to buy the plot , and it became Preston Evangelical Mission, and at some point later Preston City Mission (when Preston became a city in 2002?). It seems to have survived at least two further plans to redevelop the area, in ca 2009 and 2019. There is an photo here of it from before the Ring Road was built here . This one, in colour, from ca. 1970 here must be after the Ring Road was built, but with a building to the left...