Experimenting with supports

I need some tiny parts - cylinders 2.4 mm across, 2 mm high, with a hole in the middle. They need to be pretty accurate - bogies will rotate on them and a "top hat" pin needs to go through the hole. What is the best way to support them for printing?

Small parts need a relatively large number of supports - I have already established that - but that has a necessary loos of fidelity. My first attempt had them vertical, with three medium supports directly under it. Out of eight prints, two were useable - the rest the holes did not form, and the bases were rough on all of them, though sanding did resolve that.

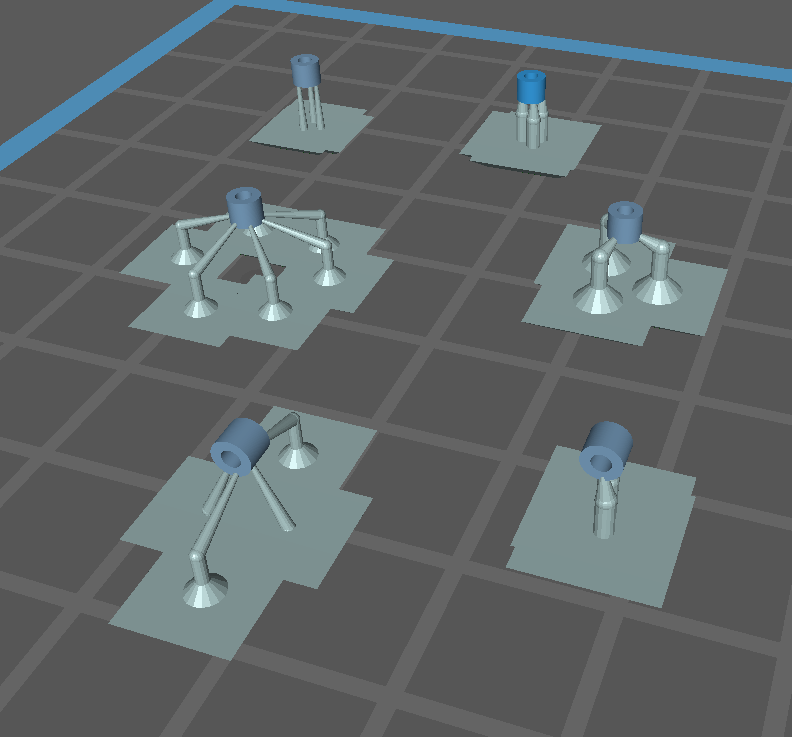

So here are six trials.

On the left, three using light supports, on the right medium supports. In the top row three supports directly under the part, in the middle row I have the supports out at the sides; this allows space for more light supports - I am pretty sure three medium is enough. On the bottom row, I have tried having the cylinder horizontal.

I did three of each, as there can be some variation. It was not a warm day (outside temperate ca. 8°C), and that will have influenced the results. Nevertheless, I was surprised to find all adhered to the plate.

Top right had the least definition at the bottom, which is what I was looking to avoid. None of them had holes that went all the way through, but I was able to drill through with a pin drill for most. In that regard, middle right was best as I could drill through with the supports in place (middle left the supports started to snap during drilling).

Overall, a bit inconclusive, but I will be happier just doing three light supports as a minimum for small parts in the future.

Comments

Post a Comment